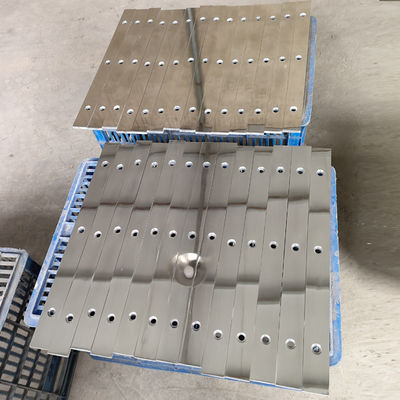

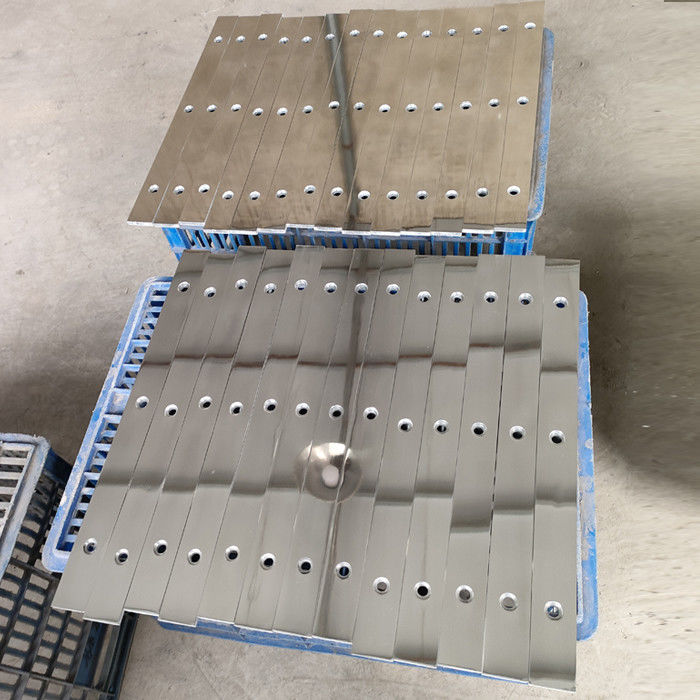

Pipeline Purge Test Iron Steam Blowing Target Plate Bolting Connection

Product Details:

| Place of Origin: | Yanshan, Hebei, China |

| Brand Name: | ZeXu |

| Model Number: | Drawing processing |

Payment & Shipping Terms:

| Minimum Order Quantity: | 30pcs |

|---|---|

| Price: | $5pcs |

| Packaging Details: | Each individual flexible packing, external wooden case packing |

| Delivery Time: | 5-7 working days |

| Payment Terms: | T/T |

| Supply Ability: | 200 pieces per day |

|

Detail Information |

|||

| Material: | Aluminum, Carbon Steel, Copper | Purpose: | Pipeline Purge Test |

|---|---|---|---|

| Shape: | Long Rectangular Cuboid | Nickname (s): | Purge Target Plate, Sputter Target Plate |

| Connection Mode: | Bolting | Surface Description: | Finish, Mirror |

| Highlight: | purge test Steam Blowing Target Plate,Steam Blowing Target Plate Bolting Connection |

||

Product Description

Pipe Steam Purge Aluminum Target Plate Mirror Iron Target Plate

1. Purpose

The purpose of this procedure is to provide the commissioning procedure for boiler steam blowing.

The boiler steam blowing is to remove deposited debris such as sand, welding dregs, rust etc. inside SH tube, RH tube and other steam pipe while manufacturing, transporting, storing and erecting.

pipe →temporary pipe → target plat →temporary pipe → atmosphere.

Other disposal and requirement for temporary pipe of steam blowing

1) All temporary pipelines before target plate should be based by argon arc weld, be treated by sandblast before installation and be carried out inner cleaning, finally accepted.

2) The temporary valves should be controlled at central control room.

3) The temporary pipe must be hanged and supported reliably and permit thermal expansion.

4) The temporary pipe must be insulated.

5) Drainage pipe and valves must be installed at each lowest point.

6) Disconnect the drainage pipes from main steam, RH steam, and HP/LP bypass to flash tank, and install temporary pipes to drain.

7) Mechanically purge the pipes which are not blown.

Avoid second pollution during the system restoring.

Trial steam blowing :

|

open temporary valves when drum pressure at respectively |

close temporary valves when drum pressure atrespectively |

| 2.0~2.2 MPa | 1.4 MPa |

| 3.0~3.3 MPa | 2.0 MPa |

| 4.0~4.4 MPa | 3.0 MPa |

![]()

![]()

![]()

![]()

![]()