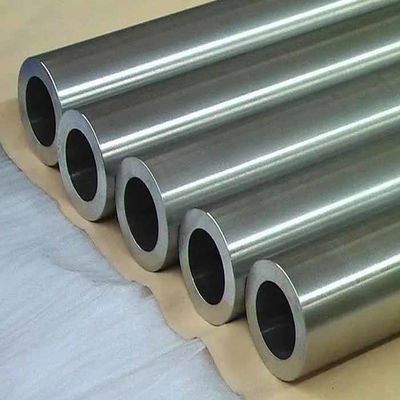

Hot Rolled Alloy 625 Seamless Pipe Inconel 625 Tube Rustproof

Product Details:

| Place of Origin: | Hebei china |

| Brand Name: | Hebei Zexu |

| Model Number: | Order please contact customer service |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Tons of |

|---|---|

| Price: | dollar 1-10Tons of 3000$ >10Tons of 2900$ |

| Packaging Details: | Wooden case packing |

| Delivery Time: | 5-10 working days |

| Payment Terms: | T/T |

| Supply Ability: | 1000Tons of/Monthly number of pcs |

|

Detail Information |

|||

| Name: | Nickel Alloy Steel Pipe | Material: | NO6625 |

|---|---|---|---|

| Technique: | Hot Rolled, Cold Drawn, Cold Finished/Hot Finished, Cold Rolled, ERW | Surface Treatment: | Round, Oval, Square, Rectangular |

| Package: | According To Customer Requirements | Length: | 6m 8m 12m |

| Highlight: | Hot Rolled Alloy 625 Seamless Pipe,Inconel 625 Tube Rustproof |

||

Product Description

Hot Rolled Nickel Base Alloy Steel Pipe NO6625 Inconel 625 Round Pipe Sold In China Factory

Nickel-based alloy refers to a class of alloys with high strength and certain antioxidant corrosion resistance at 650~1000℃. According to the main properties, it is subdivided into nickel-based heat resistant alloy, nickel-based corrosion resistant alloy, nickel-based wear resistant alloy, nickel-based precision alloy and nickel-based shape memory alloy. According to the different matrix, superalloy is divided into: iron based superalloy, nickel based superalloy and cobalt based superalloy. Nickel-based superalloy is referred to as nickel-based alloy.

According to the main properties, it is subdivided into nickel-based heat resistant alloy, nickel-based corrosion resistant alloy, nickel-based wear resistant alloy, nickel-based precision alloy and nickel-based shape memory alloy

Nickel-based alloys are used in many fields, such as:

1. Ocean: Marine structures in the Marine environment, seawater desalination, mariculture, seawater heat exchange, etc.

2, environmental protection: thermal power generation of flue gas desulfurization equipment, wastewater treatment.

3. Energy field: nuclear power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical field: oil refining, chemical equipment, etc.

5. Food field: salt production, soy sauce brewing, etc. In the above many areas, ordinary stainless steel 304 is not competent, in these special areas, special stainless steel is indispensable, but also can not be replaced. In recent years, with the rapid development of the economy, with the continuous improvement of the level of the industrial field, more and more projects need higher grade stainless steel. With the growth of demand for nickel-based alloys in various industries. In 2011, China's nickel-based alloy market reached 23.07 billion yuan, with a year-on-year growth rate of 19.47%. Therefore, the development level of the industry is in a steady upward trend.

Smelting: In order to obtain a more pure and purified molten steel, reduce the gas content and harmful element content; At the same time, due to the existence of easily oxidized elements such as Al and Ti in some alloys, non-vacuum smelting is difficult to control; In order to obtain better thermoplasticity, nickel-based heat-resistant alloys are usually smelted in vacuum induction furnaces, or even produced by vacuum induction smelting plus vacuum consumable furnaces or electroslag furnaces.

In terms of deformation: forging, rolling process is used, and even rolling after extrusion or direct extrusion process with mild steel (or stainless steel) cladding is used for alloys with poor thermoplasticity. The purpose of deformation is to break the casting structure and optimize the microstructure.

Casting: The master alloy is usually melted in a vacuum induction furnace to ensure composition and control gas and impurity content, and the parts are made by vacuum remelting and precision casting.

Heat treatment: deformed alloys and some cast alloys need to be heat treated, including solid solution treatment, intermediate treatment and aging treatment, taking Udmet 500 alloy as an example, its heat treatment system is divided into four stages: solid solution treatment, 1175℃, 2 hours, air cooling; Intermediate treatment, 1080℃, 4 hours, air cooling; One time aging treatment, 843℃, 24 hours, air cooling; Secondary aging treatment, 760℃, 16 hours, air cooling. In order to obtain the required organizational state and good comprehensive performance.

![]()

![]()

![]()

![]()

![]()